A wide range of competence

Manufacturing

and services using dry ice

Our manufacturing is based on high-capacity equipment by Cold Jet. The production process takes place in a specially designed facility which ensures top quality of the final product. Higher efficiency of equipment means a shorter time needed to fill in a container and dispatch it to the customer.By using the Cold Jet equipment, we make granulate of higher durability and resistance which prolongs free sublimation time.Our storage tanks for liquid C02 and all pipelines are fully made of stainless steelwhich allows our pellets to be used in contact with food and biological materials.

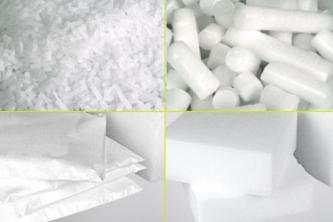

We offer two types of pellets:

- pellets of Ø3mm diameter mainly used for cleaning and less for cooling purposes and special effects

- pellets of Ø16mm diameter which is broadly used in refrigeration and food transport

We arrange dispatch according to our customers' needs using dedicated transport or forwarding agents. Up to 50 kg of pellet is sent in special Styrofoam packages for dry ice · transport.Quantities higher than 50 kg are delivered in professional containers insulated with polyurethane foam.The containers allow storage of dry ice longer than Styrofoam packages.The storage period during which the products keeps all its properties is up to 72 hours.

PROJAN can deliver its product in any amount to any destination in the country. Our distribution system combined with high capacity of the manufacturing equipment ensures constant deliveries of fresh pellet. Our priorities are guarantee, satisfaction and content of each customer - that is why our service department is particularly focused on timely and quality deliveries.